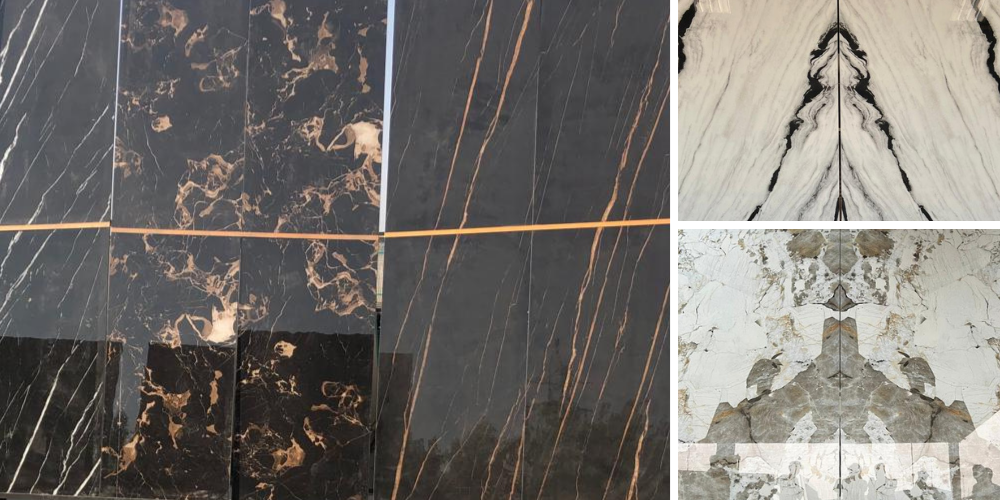

In architectural and commercial projects, porcelain slabs are expected to deliver more than visual appeal. Performance, consistency, and reliability become equally important, especially at larger formats. Let us explore why quality considerations are central to successful slab selection.

What Are Porcelain Slabs?

Porcelain slabs are large-format ceramic surfaces manufactured using refined natural raw materials, compacted under high pressure and fired at high temperatures. Unlike some decorative surface materials, porcelain slabs are engineered products which are designed to deliver low porosity, structural stability, and surface consistency across large dimensions.

Their defining characteristic is not just size, but uniform performance across the entire slab, which requires precise control at every stage of manufacturing.

Porcelain Slabs vs Standard Porcelain Tiles

While both belong to the same material family, porcelain slabs differ significantly from standard tiles in scale and manufacturing sensitivity.

Large formats demand tighter control over pressing, firing, and finishing. Minor inconsistencies that may be acceptable in smaller tiles become more problematic when scaled up to slab dimensions. As a result, slab production requires higher precision, stricter quality checks, and more controlled handling throughout the process.

Why Quality Matters More in Large-Format Slabs

Quality plays a larger role in porcelain slabs because size magnifies imperfections. Variations in thickness, density, or surface stability can affect not only appearance, but also installation accuracy and long-term performance.

Uniform pressing ensures consistent slab density and thickness. Controlled firing directly influences strength, water absorption, and internal stability. Surface finishing impacts both visual consistency and functional performance. When these elements are precisely managed, slabs perform reliably across demanding applications.

Key Quality Parameters to Understand

When evaluating porcelain slabs, buyers and specifiers should look beyond surface appearance and consider a few essential technical parameters:

- Dimensional consistency to ensure slabs align correctly during installation

- Thickness uniformity for structural balance and load distribution

- Low water absorption, indicating proper firing and material density

- Surface stability and finish consistency across the slab

- Accurate edge calibration for tight joints and clean layouts

Each of these factors contributes to how well a slab performs once installed.

Closing Note

Porcelain slabs combine design flexibility with engineered performance. Understanding what defines quality helps architects, specifiers, and buyers make informed choices that extend beyond aesthetics and support long-term reliability.